Consultancy

- ISO 9001:2015

- ISO 9001:2008

- ISO 14001

- ISO 14001-2015

- ISO 50001 EnMS

- ISO/TS 16949:2009

- OHSAS 18001

- ISO 22000 FSMS

- ISO 27001 ISMS

- ISO 13485:2003

- ISO/IEC 17025:2005

- ISO 15189: 2003

- AS 9100

- TL 9000

- SA 8000

- HACCP

- Lean manufacturing

- Total Quality Management (TQM)

- Total Productive Maintenance(TPM)

- CE marking

- Clean Development Mechanism

- PAS99

- ISO-TS-14067 Carbon Footprint

For Enquiry & Information

SMS: <ISO> 9423005866

Email: technosyscon@gmail.com

Call:9423005866

TPM Consultants In Pune India

What is Total Productive Maintenance ( TPM ) ? |

||||||||||||||

| It can be considered as the medical science of machines. Total Productive Maintenance (TPM) is a maintenance program which involves a newly defined concept for maintaining plants and equipment. The goal of the TPM program is to markedly increase production while, at the same time, increasing employee morale and job satisfaction. TPM brings maintenance into focus as a necessary and vitally important part of the business. It is no longer regarded as a non-profit activity. Down time for maintenance is scheduled as a part of the manufacturing day and, in some cases, as an integral part of the manufacturing process. The goal is to hold emergency and unscheduled maintenance to a minimum. TPM - History |

|

|||||||||||||

TPM is a innovative Japanese concept. The origin of TPM can be traced back to 1951 when preventive maintenance was introduced in Japan. However the concept of preventive maintenance was taken from USA. |

||||||||||||||

| Nippondenso was the first company to introduce plant wide preventive maintenance in 1960. Preventive maintenance is the concept wherein, operators produced goods using machines and the maintenance group was dedicated with work of maintaining those machines, however with the automation of Nippondenso, maintenance became a problem as more maintenance personnel were required. So the management decided that the routine maintenance of equipment would be carried out by the operators. ( This is Autonomous maintenance, one of the features of TPM ). Maintenance group took up only essential maintenance works. Thus Nippondenso which already followed preventive maintenance also added Autonomous maintenance done by production operators. The maintenance crew went in the equipment modification for improving reliability. The modifications were made or incorporated in new equipment. This lead to maintenance prevention. Thus preventive maintenance along with Maintenance prevention and Maintainability Improvement gave birth to Productive maintenance. The aim of productive maintenance was to maximize plant and equipment effectiveness to achieve optimum life cycle cost of production equipment. By then Nippon Denso had made quality circles, involving the employees participation. Thus all employees took part in implementing Productive maintenance. Based on these developments Nippondenso was awarded the distinguished plant prize for developing and implementing TPM, by the Japanese Institute of Plant Engineers ( JIPE ). Thus Nippondenso of the Toyota group became the first company to obtain the TPM certification. Why TPM ? Similarities and differences between TQM and TPM :

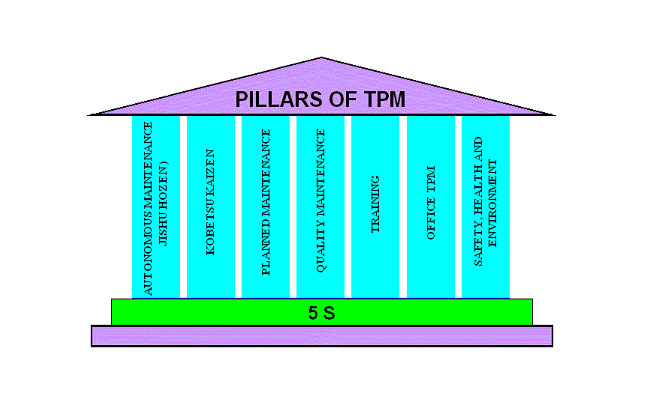

Pillars of TPM

|

||||||||||||||